DIG3D.Fix

DIG3D.Fix

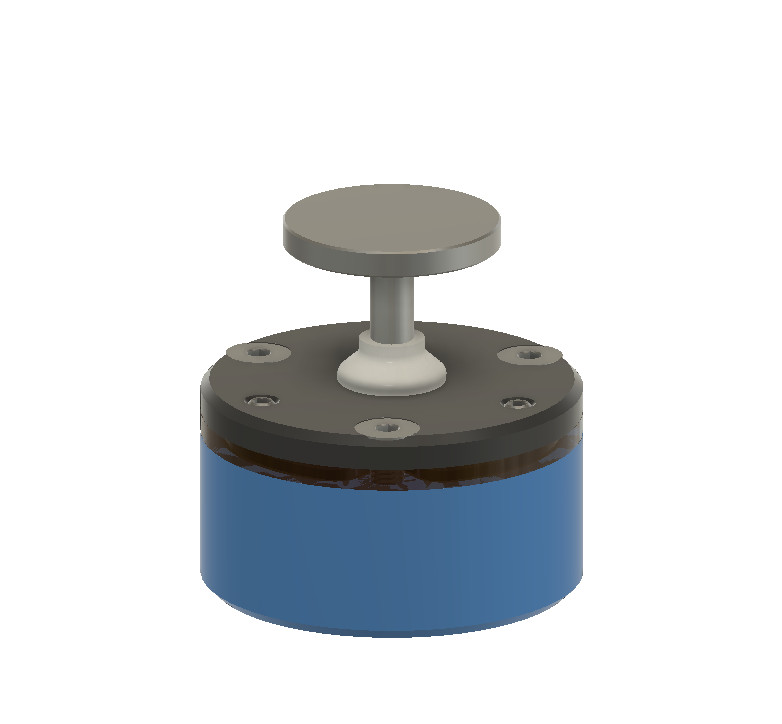

3 axis, worktable fixed, tool length & diameter sensor

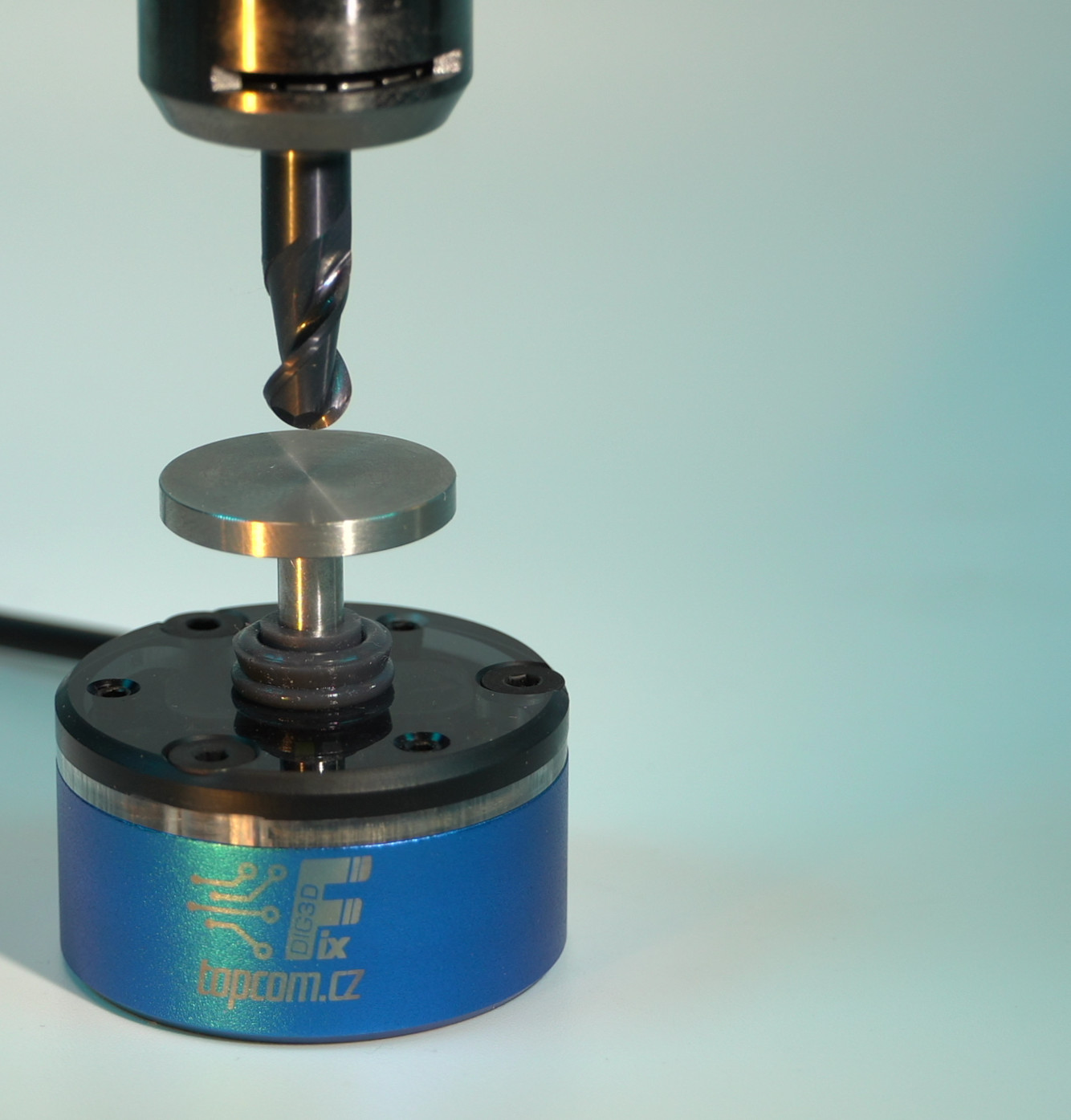

A 3-axis sensor mounted on the CNC machine’s worktable is used for automatic tool measurement, specifically for measuring tool length and diameter. Using a touch plate, the probe detects contact with the tool along the X, Y, and Z axes, allowing for precise tool offset adjustments directly during the machining process. Tool length is measured in the Z-axis direction, while the diameter is measured by touching the tool in the X or Y axis during a slow reverse rotation. This type of probe significantly increases production efficiency, eliminates the need for manual measurement, and minimizes errors caused by human factors. As a result, it ensures higher machining accuracy and repeatability.

DIG3D.Fix

A 3-axis sensor mounted on the CNC machine’s worktable is used for automatic tool length and diameter measurement. Tool length is measured in the Z-axis direction, while the diameter is measured by touching the tool in the X or Y axis during a slow reverse rotation.

Configuration

slide the pictures to explore all available features

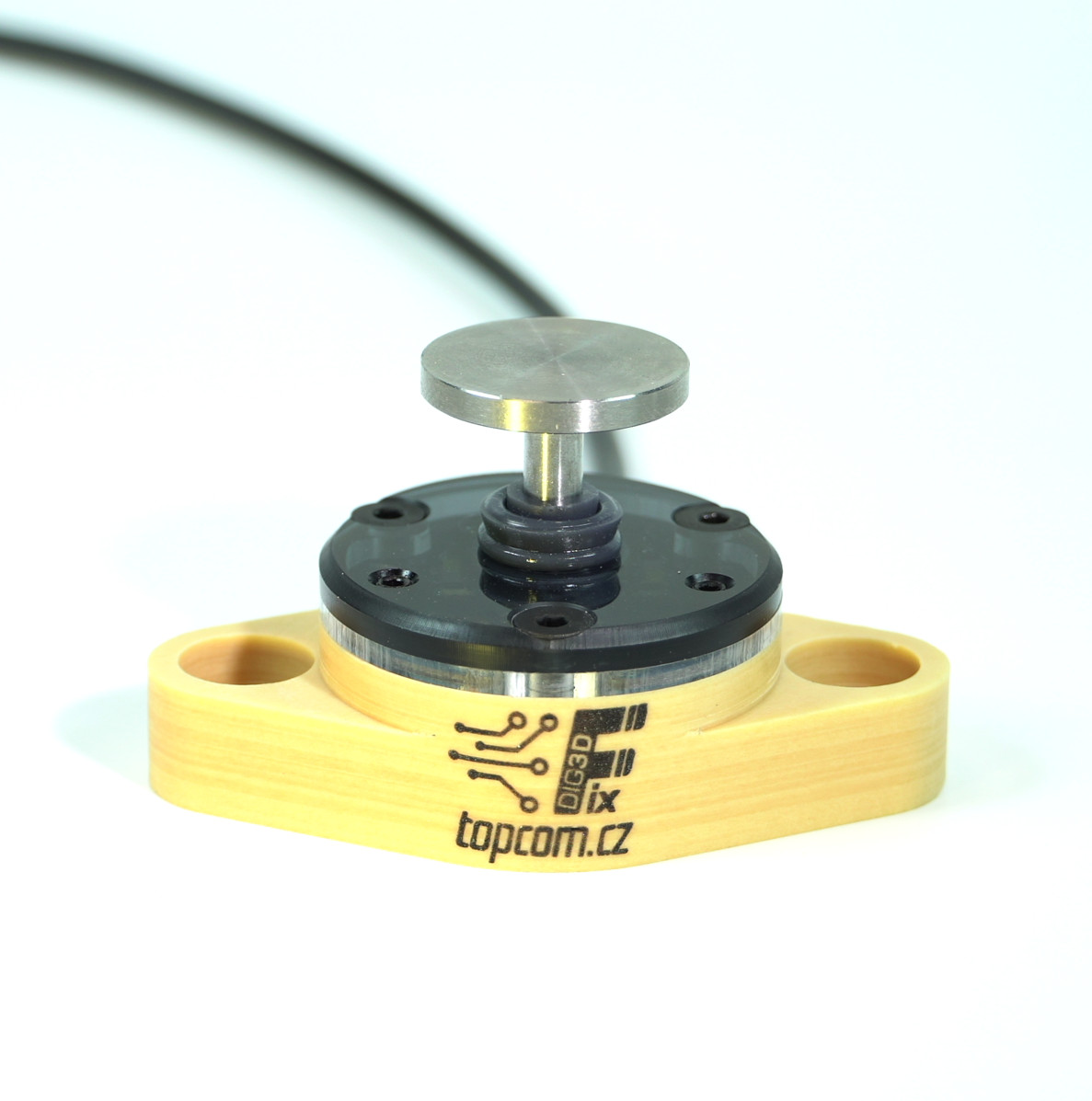

Alu alloy body

With a central screw

Plastic body

With two screws on the sides

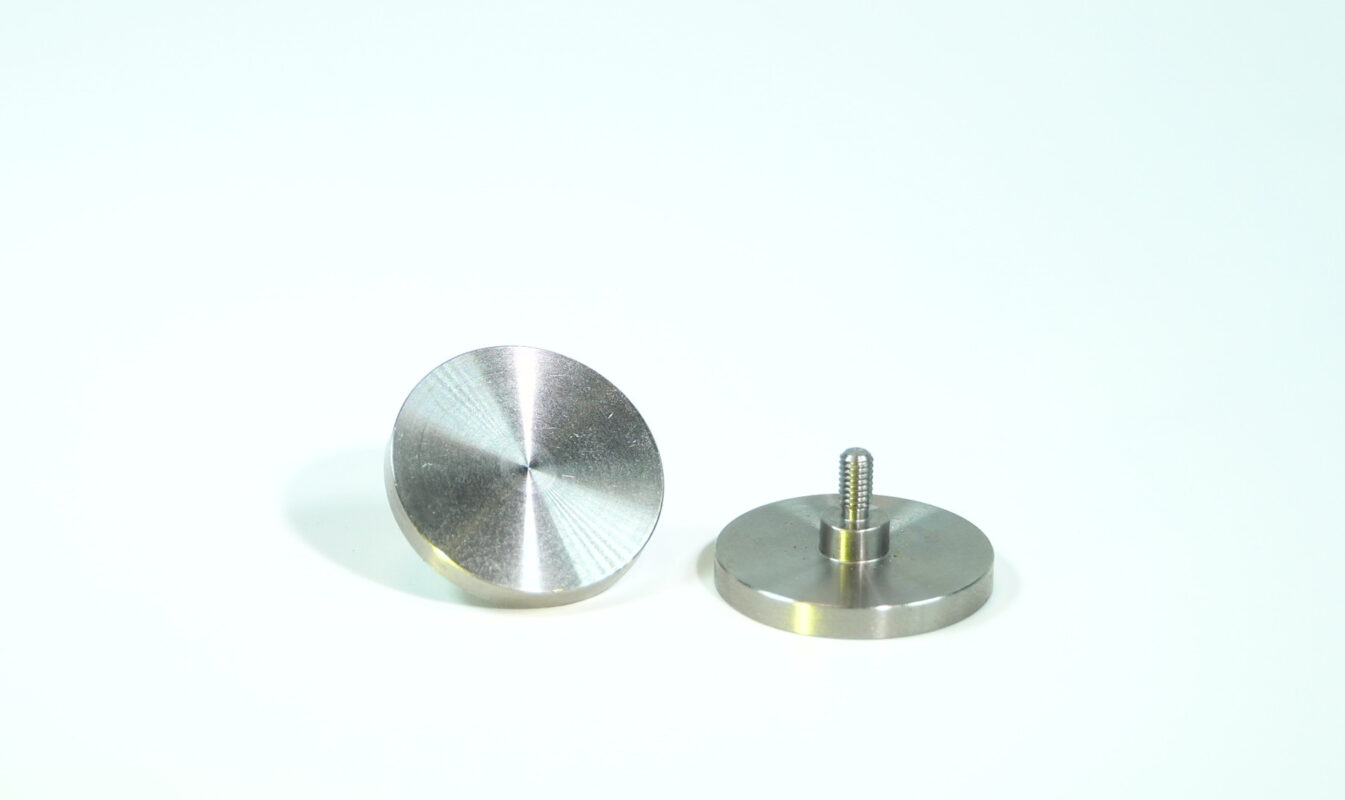

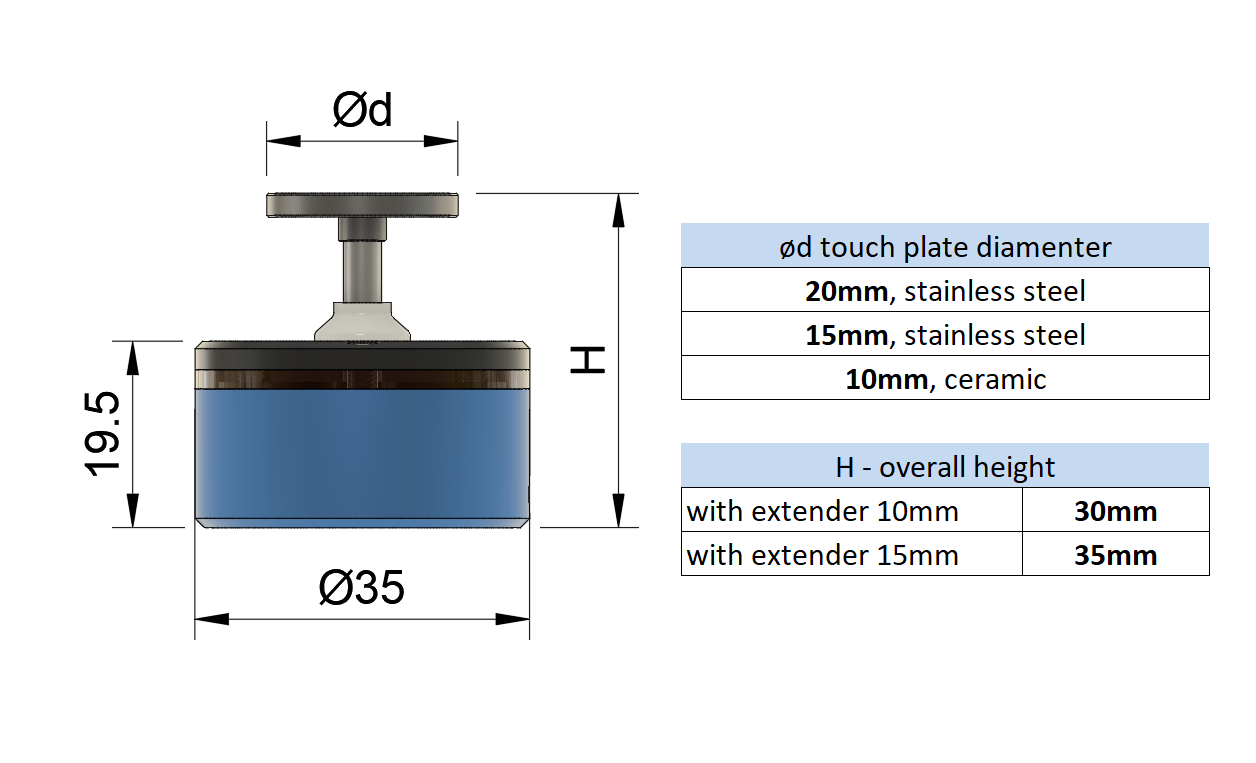

M2.5/⌀20mm stainless steel touch plate

M2.5/⌀15mm stainless steel touch plate

M2.5/⌀10mm ceramic touch plate

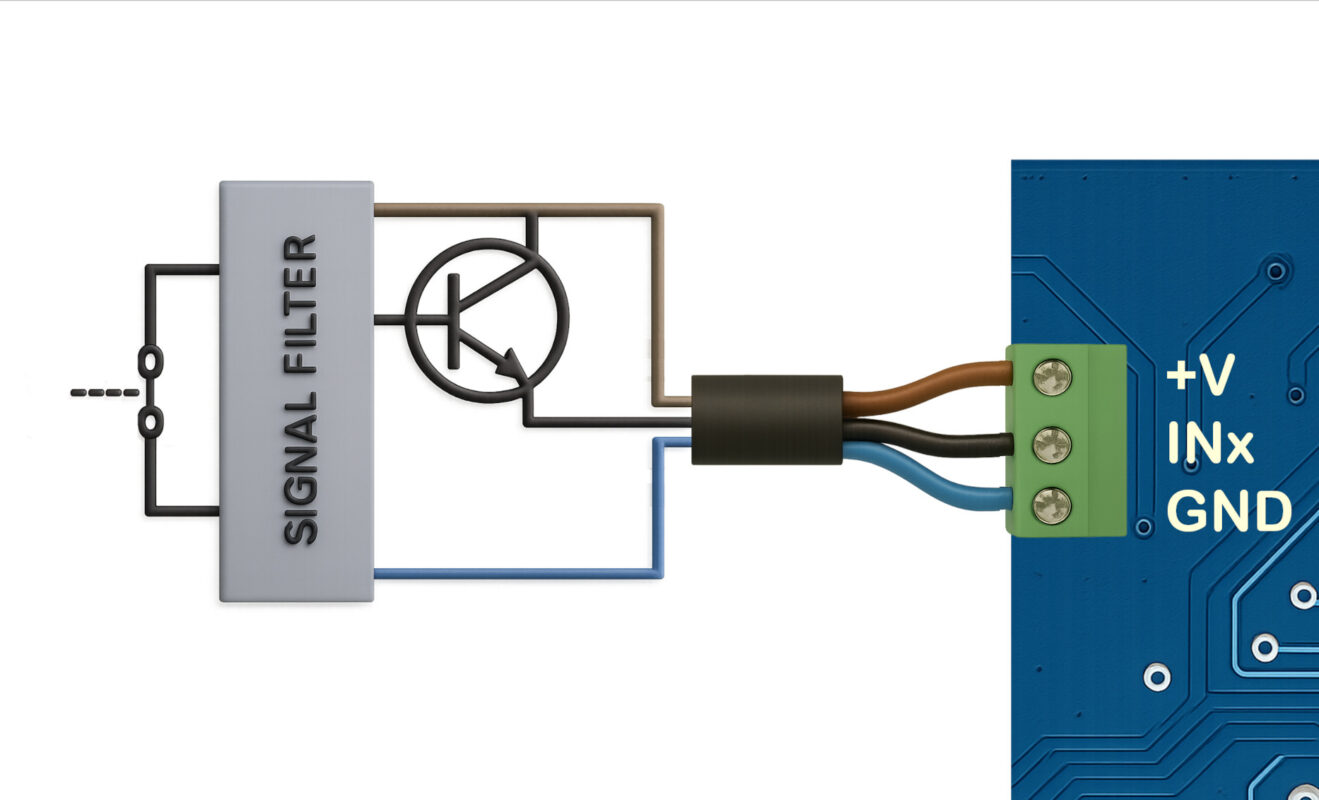

PNP output

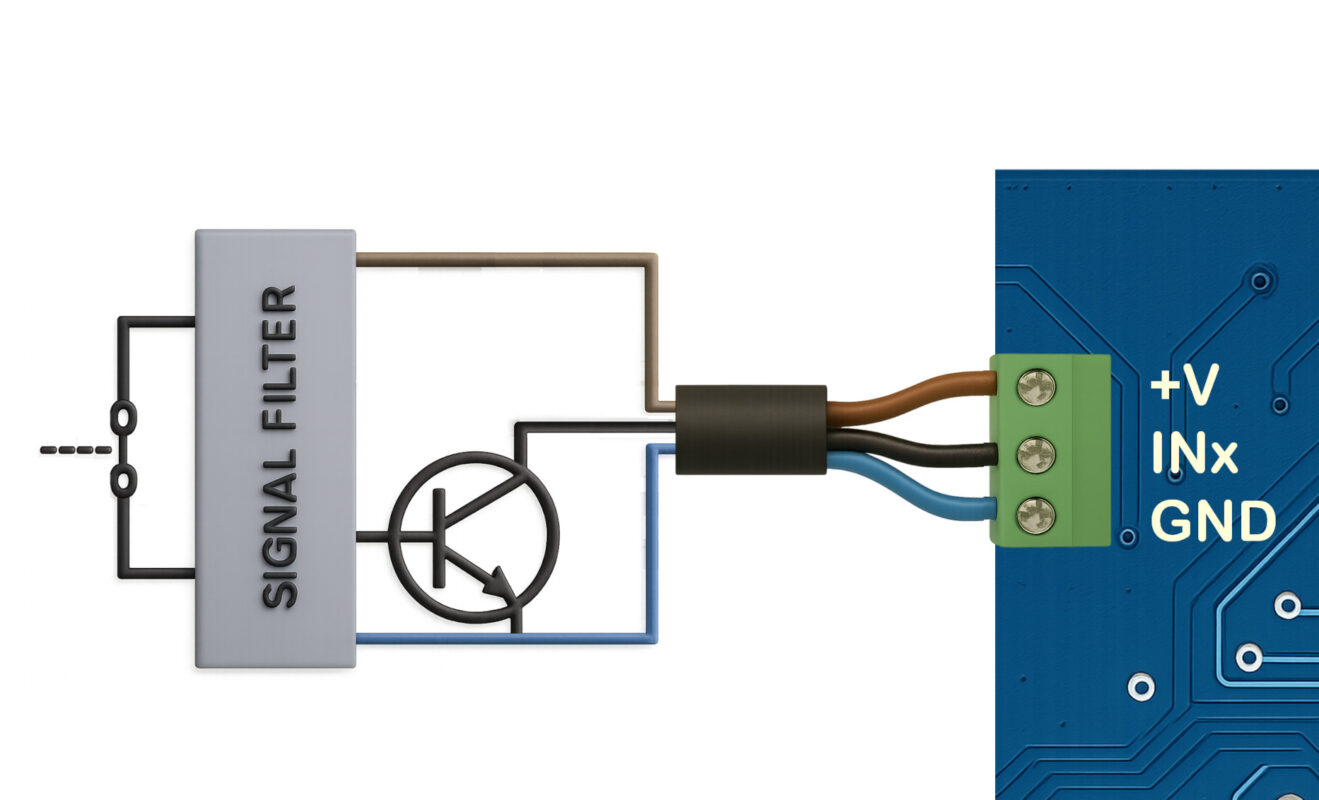

NPN output

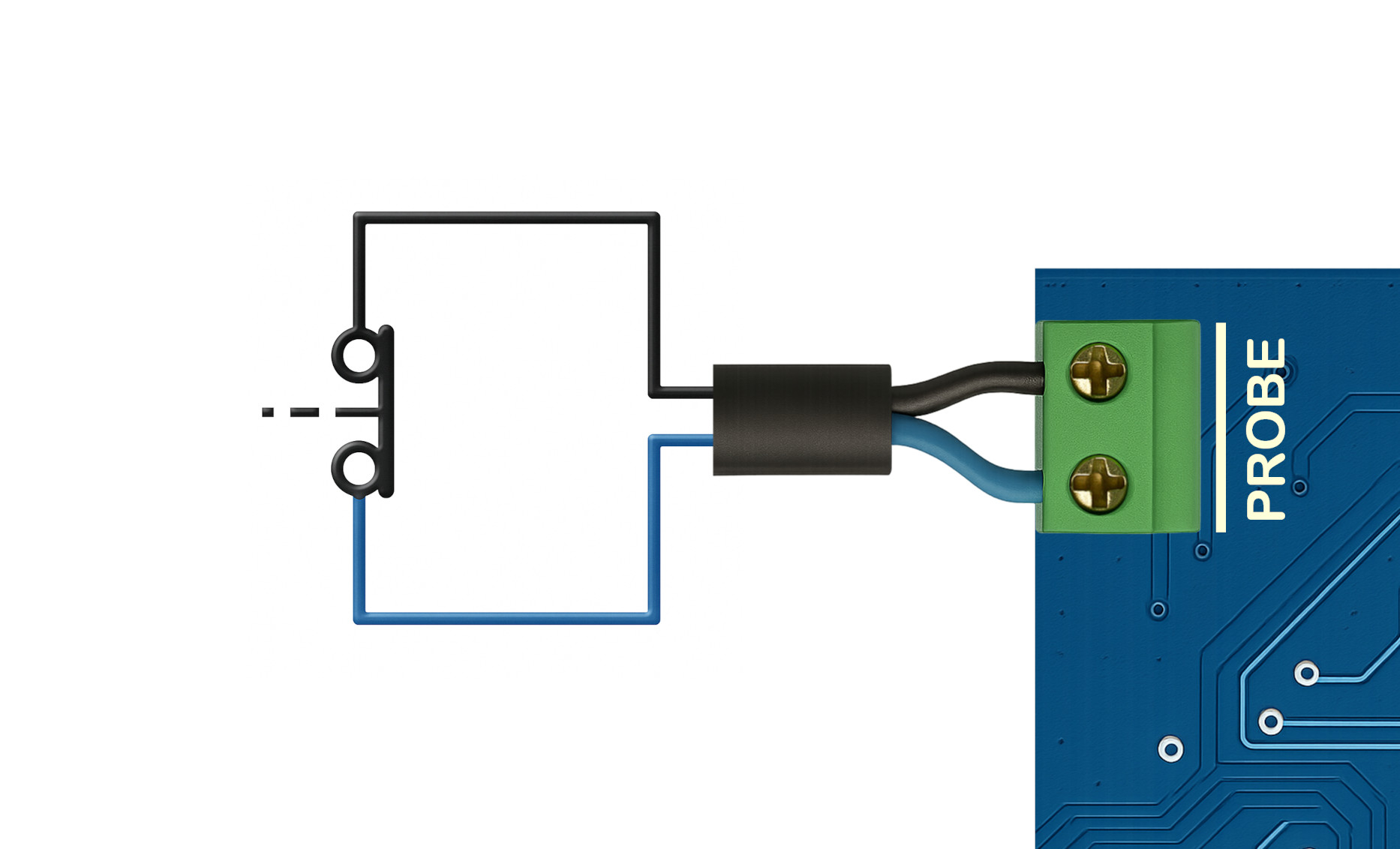

Switch only (2wires)

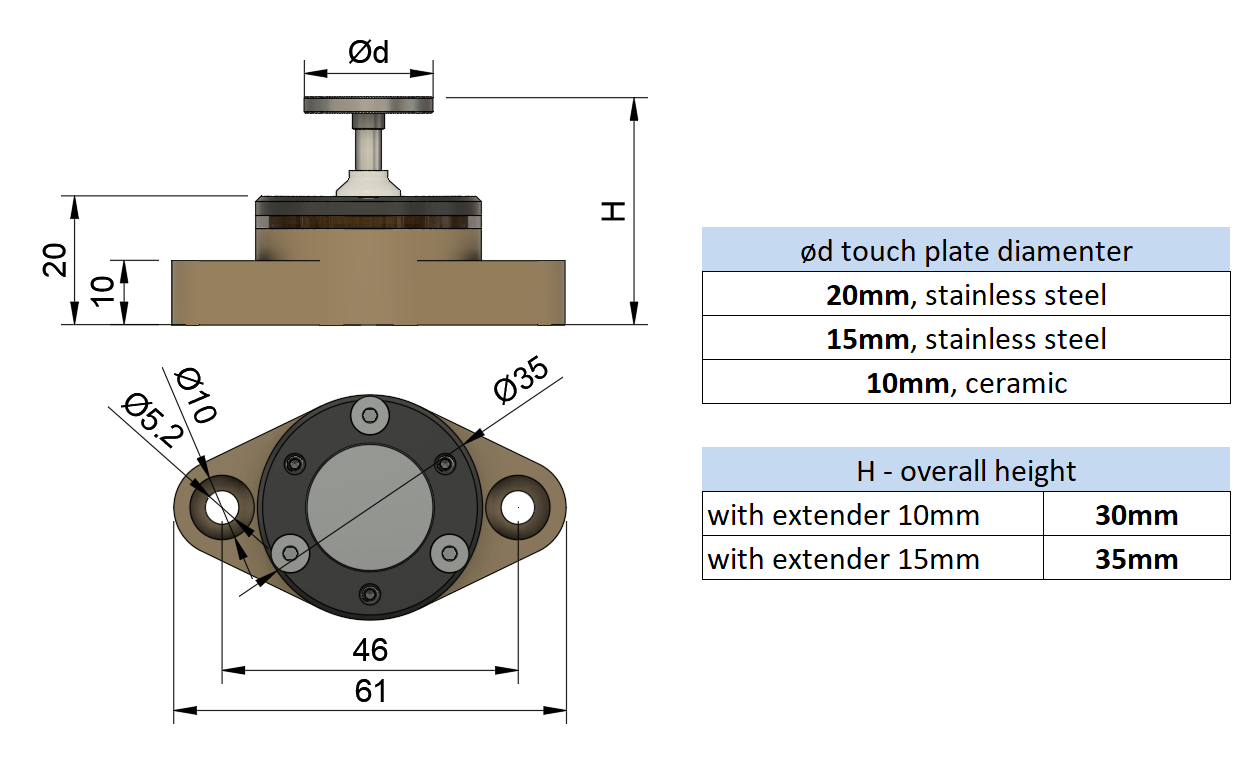

Drawing

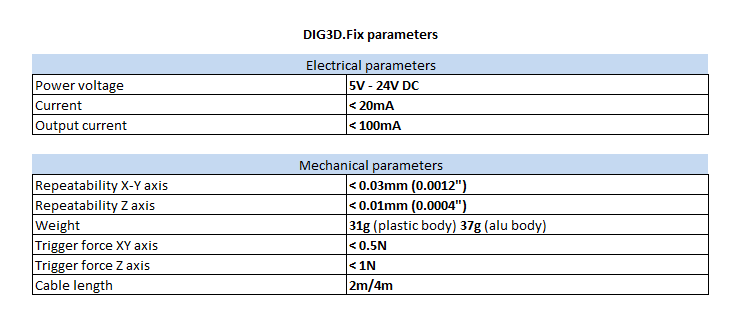

Parameters

Download