CNC machines contain a lot of sensors. The most common are limit switches, tool length sensor, edge finder etc. These sensors are connected to digital inputs of motion control board. Sometimes is necessary to merge more signals together from several reasons. The first main reason is limit of digital inputs number in the motion control board.

The second reason is usually connected with the motion control software. Some of them (for ex. MACH3) have only one input for probing. If you need to connect more probes (TLS, edge finder, …) you have to merge the signals together or switch them.

Simple switches

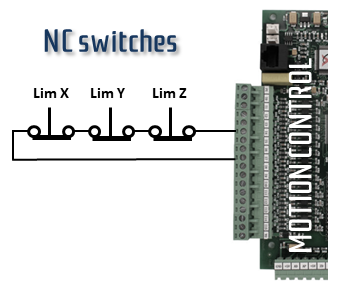

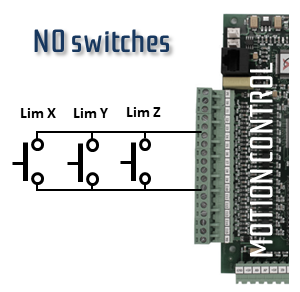

Solution is easy in case of simple switches.

Normally closed (NC) simple switches are ordered in row (serial ordering). NC switch is closed, when not triggered, and whole circuit is closed. Triggering of any switch will cause to open the circuit.

Normally open (NO) simple switches are connected in parallel ordering. NO switch is open, when not triggered, and whole circuit is open. Triggering of any switch will cause to close the circuit.

Active sensors

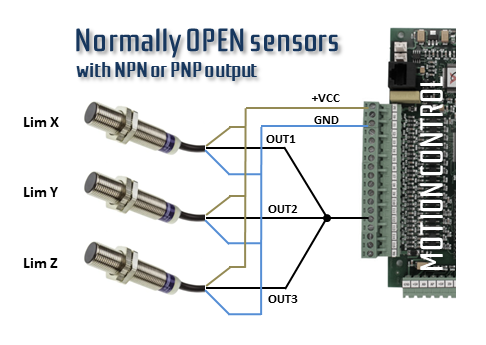

Active digital sensors are usually provided with NPN or PNP output. NPN means, that output line is switched to GND, when an output is active. PNP means, that positive power line is switched to output line, when output is active. When an output is not active, output line is disconnected (high impedance). Sensors can be also in normally open (NO) or normally closed (NC) configuration.

Merging signals from normally open sensors is not an issue, because normally open sensors have disconnected output, when not triggered. So if the sensor is not triggered, it does not affect any other sensor. In this case is possible to connect the outputs from the sensors to one line. Any triggered sensor will activate the output line. This works, for sure, only when normal status of each sensor is “untriggered”.

Major disadvantage of normally open sensor is, that motion control does not have active signal, since any sensor is triggered. It is bit dangerous, especially when sensors are connected by some connectors. When the wire from the sensor is broken, signal is not going through to the motion control and some damage or injury can happen.

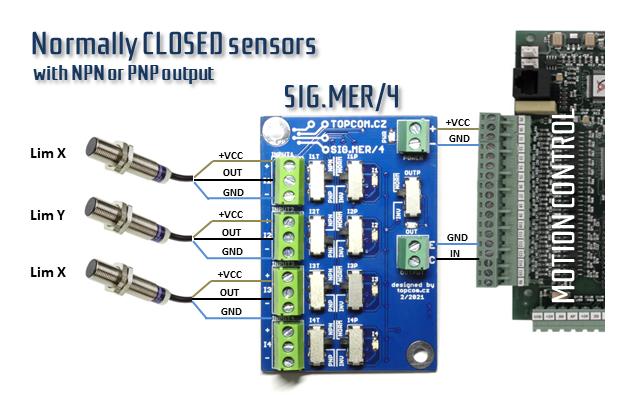

More safe are normally closed sensors. NC sensor provides the active output, till the sensor is triggered. It is advantage, because if something is wrong on the line between the sensor and motion control, signal does not go through and motion control can react immediately, because the sensor seems to be active.

It is necessary to use a few electronic components, to merge the signals from normally closed sensors. This circuit is realized by SIG.MER/4, signal merger board. To be as flexible as possible, this component is designed with the configurable inputs, allows to setup NPN/PNP output polarity, and NO/NC signal phase independently for each input. Output signal is completely isolated from the power supply and can be wired as NPN or PNP output to the motion control. Also output phase (normal/inverted) can be set by slide switch on the board.

For more information about this product please visit the product page.

Connecting the CNC probes

CNC probes, like tool length sensor, edge finder etc., are technically the same like sensors or switches. Simple one are only mechanical switch, the other one have some internal electronics for signal filtering, signal conversion etc.

While sensors like limit switches are usually connected permanently to the system, it is useful to have possibility to disconnect the probe, when the probe is not used, and store it on some safe a clear place. In this point you are faced with the issue of signal merging described above. Normally open probes are not safe, especially when are not permanently connected to the system, normally closed probes are safe, but if you disconnect it, it seems like sensor is triggered.

Here are the several solutions with topcom products. Let’s go through from the simple one to the more complicated.

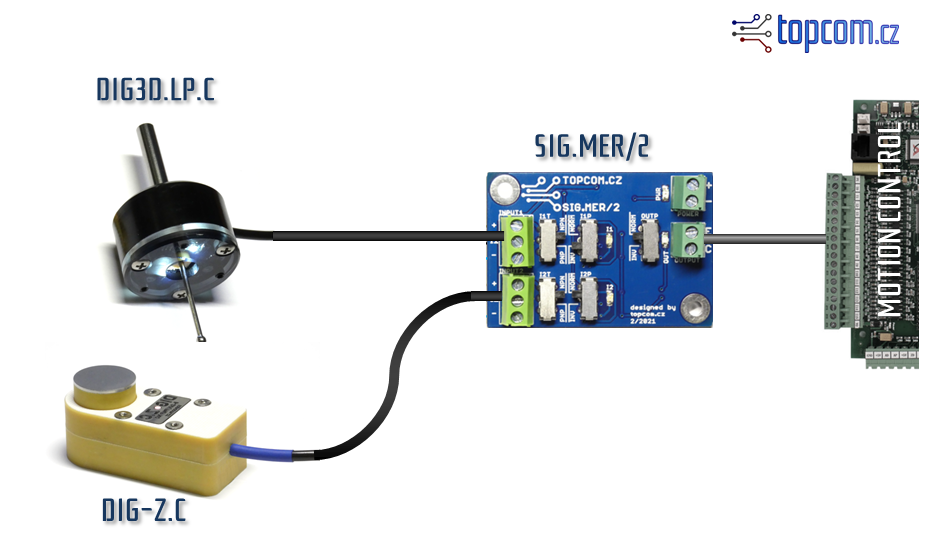

Simple solution, where edge finder (DIG3D) and tool length sensor (DIG-Z.C) are permanently connected to 2 channel signal mergher (SIG.MER/2). Sensors can be NO or NC, NPN or PNP.

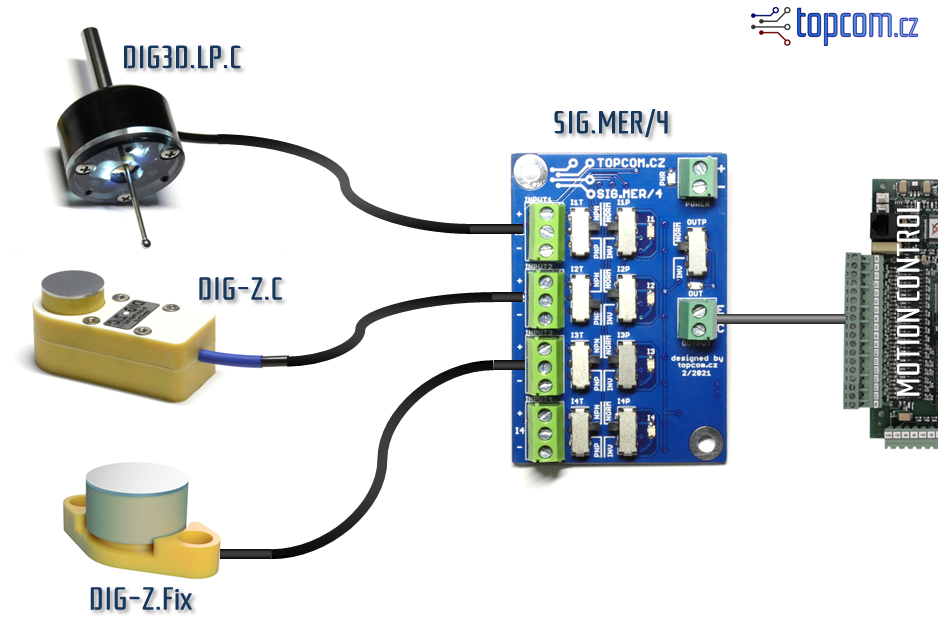

Solution similar to the previous one, but beside of edge finder (DIG3D) and tool length sensor (DIG-Z.C) is connected also Z-axis TLS fixed to a CNC table (DIG-Z.Fix). All sensors are permanently connected to the 4 channel signal merger (SIG.MER/4). Sensors can be NO or NC, NPN or PNP.

Simple, but very effective solution. You can connect edge finder (DIG3D.LP.M) or TLS (DIG-Z.M), by magnetic connector. Advantage of this solution is, that you can use normally closed sensors, and you do not need to merge their signals, because both sensors share the same magnetic connector and you can connect only one sensor in the same time. The next advantage is, that if you forge to connect any sensor, and you have sensors in normally close configuration, from the point of view of the motion control it seems, that sensor is triggered, and motion control will not start the measurement at all.

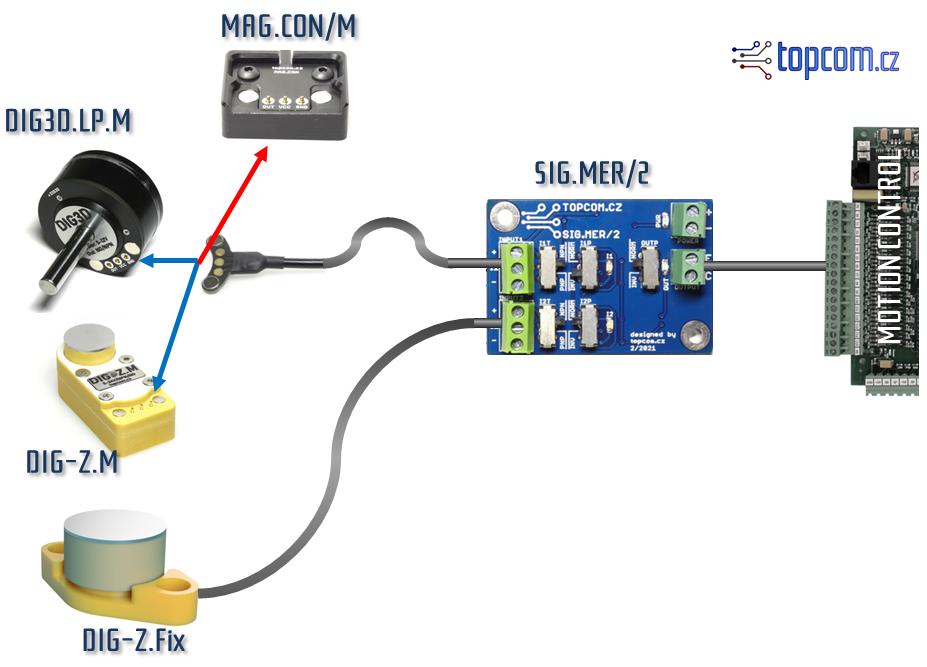

If you need to connect, beside the probes with a magnetic connector, also TLS fixed to the CNC table (DIG-Z.Fix), you need to use the signal merger (SIG.MER/2). Disadvantage of this solution is, that the probes with a magnetic connector have to be in normally open configuration. Which is not safe. This solution is not preferred, but also possible.

This solution is improvement of the previous one. Fixed TLS (DIG-Z.Fix) is connected permanently, and probes with magnetic connector DIG3D.LP.M and DIG-Z.M can be in NC configuration, because when cable is not used, it is docked in magnetic connector MAG.CON/M, which simulates the NC output. You can use NC sensors, but still it is not perfect, because if you forget to connect the sensor and the magnetic connector remains in the dock, from the motion control point of view it seems, that sensor is ready, and not triggered. You have to be careful to connect the connector each time.

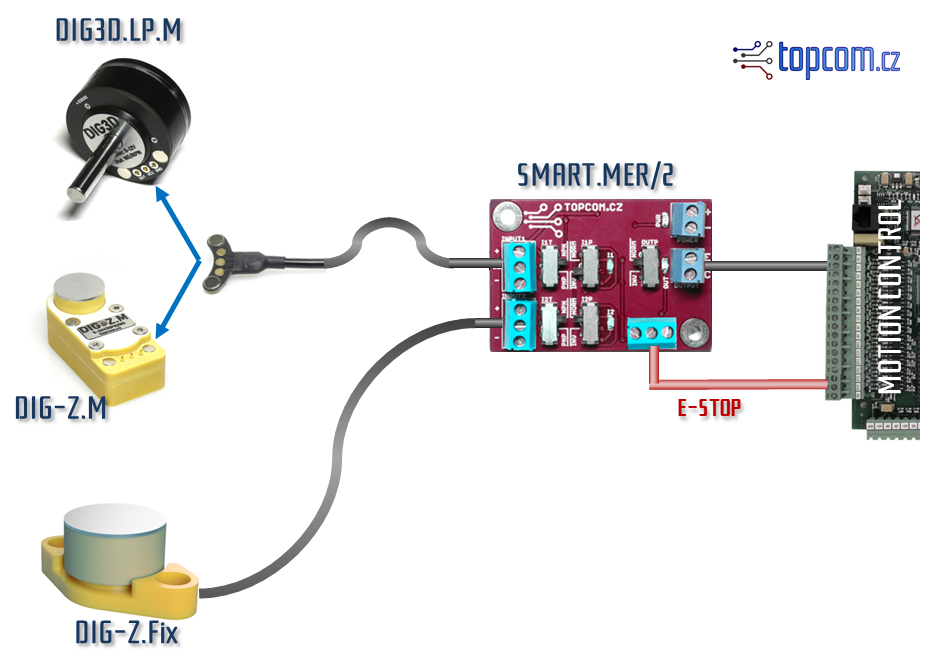

Ultimate solution is coming! It’s name is Smart merger. Smart merger (SMART.MER/2) has the same function like the standard merger, but has also two additional functions.

Smart merger can detect, if the sensor is connected or not. If the sensor is not connected, input channel is disabled and input signal is not merged with the others. Based on this function, you can use normally closed sensors with a magnetic connector, but if they are disconnected, input channel is disabled automatically.

The second function of the Smart merger is Probe saver. Enabling this function, Smart merger will generate E-STOP signal, when probe is activated out of the measurement cycle. If the probe is activated accidentally during a probing preparation, Smart merger will stop a machine to avoid any damages.

Picture of the Smart merger is illustrative only so far, but this product will be released soon.

Hoping that you found your solution here. If not, just send me the email to topcom@topcom.cz and I will try to find some 😉

Created by Lukas, 9/2021

![]()